Where machines are brought to life

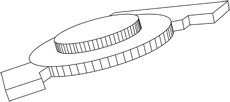

| Assembly in the Rundhalle (“Round Hall”) "One must have the future in one’s mind and the past in the files." > Charles Talleyrand, french statesman, 1754-1838 The "Rundhalle" is not just Binder+Co’s production centre but also a highlight of industrial architecture:

___________________________________ Nowadays, mechanical production, assembly and trial runs of the machines, particularly BIVITEC and DRYON, take place in the Rundhalle. BIVITEC is an example of the success story created by Binder+Co’s innovative strength and expertise. The screening machine was developed in the 80s to screen damp coal. Screening works poorly on conventional machines because the screen openings become blocked. As a result, Binder+Co developed a special screening machine with dynamically excited screen panels. The problematic screening material is thrown out of the screen openings at high speed to enable efficient screening. BIVITEC was the crucial development which led to Binder+Co becoming the global market leader in the separation of difficult-to-screen materials. Facts about BIVITEC:

___________________________________ DRYON is the particularly gentle and efficient fluidized-bed dryer developed by Binder+Co. The dryer’s vibration and the hot air flow create a fluidized bed.

Drying technology Further details can also be found on the Binder+Co website: > BIVITEC special screening machine > DRYON dryer |

|

0 0 |

|